The copper tube fin type high efficiency tube machine model FIN25 can simultaneously process the outer wings and inner teeth of the pipe, and can produce various specifications of heat exchange fin tubes which are required by the heat exchanger. The tube is made of annealed copper and various copper alloys.

This machine can according to user requirements, continuous rolling fin (i.e. pipes except both ends, the rest of the fin continuous and uniform) and discontinuous fin (i.e. pipes except both ends, the rest at regular intervals respectively fin segments and smooth section). The length of the optical section is greater than 20mm and can be adjusted arbitrarily. The number of optical segments can also be set. There are two modes of operation, manual or automatic, whether continuous rolling or intermittent rolling. The whole process is controlled by PLC.

The general process flow of fin tube processing and subsequent treatment:

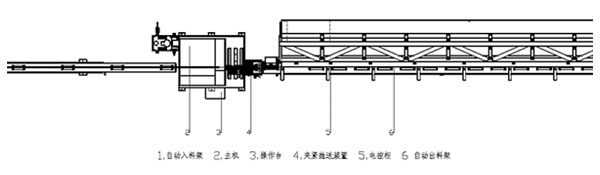

The soft state of fixed length of straight pipe blank (fixed length cutting, deburring equipment etc. in addition to manual handling equipment) to fin machine and arranged into automatic blank holder, automatic feeding mechanism to control each pipe to be processed into the position, the motor pushes the guide rod straight tube into the inner mandrel and wait for rolling - fin the host feed rolling processing, on the tube (straightening process, optional), fixed length cutting, cleaning or passivation treatment, pressure test and drying treatment, product inspection and packaging

|

Technical parameter: |

|||||

|

1 |

Material status of tube blank |

Soft copper tube (straight pipe) |

|||

|

2 |

Product range |

Ф15.88~Ф25.4×(0.8~1.4)mm |

|||

|

3 |

Fin parameter |

MAX.Height:1.5mm |

|||

|

4 |

Max.pipe speed |

2100rpm |

|||

|

5 |

Fin distance |

The number of fins per inch is19~55;Typical sizes are 19、26、33、42、50、55 ect,Determined by the combination of blades and gaskets. |

|||

|

6 |

Product length |

MAX.8m |

|||

|

7 |

MAX.Knife shaft speed |

600rpm(single);Stepless adjustment |

|||