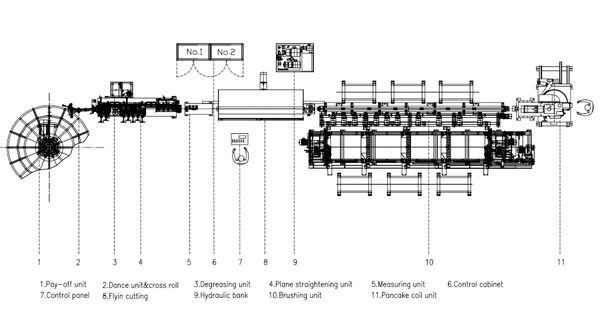

The pay-off unit and straightening unit are both driven by 3-phase AC motor. The key part of cutting in line is controlled by servo driver and servo motor, so that the cutting precision can be within ±1mm and can reach the first class level all over the world. The running process of the whole machine is controlled by PLC, so that the real-time alarm, stop automatically when broken tube, tube piling, and no tube.

With horizontal and vertical straightening rollers, the straightening of high precision can be achieved. The cutting unit adopts pneumatic motor. On the premise of stable output, it can decrease the inertia greatly, so that the machine running speed will be greatly increased.

The pancake coiler machine can be devided into downward type and upward type. The downward type pancake coiler can wind the tube of more than 30m.

|

Technical parameter: |

|||||

|

1 |

Material |

Hard or semi-hard copper tube in basket |

|||

|

2 |

tube dimension |

4mm×0.35mm≤φ≤28.58mm× 1.5mm; |

|||

|

3 |

Basket dimension |

OD:Ø3050;Height:1400mm; |

|||

|

4 |

Re-cutting length and precision |

2.2m≤L≤6m±2mmor the length can be changed as per customer’s requirement. |

|||

|

5 |

Production speed |

Normal working speed:30~100M/min, max. working speed can reach 120m/min |

|||

|

6 |

Select function |

The qualified product and unqualified product can be selected. |

|||

|

7 |

Pancake coiler |

pancake coiler length:9~200m; |

|||